In heavy industrial fabrication, we obsess over the big things. We plan the crane lifts down to the inch, qualify every welder, and X-ray every critical seam. A project can be 95% complete—a massive, gleaming testament to engineering and hard work sitting on the assembly pad. Everything is on schedule.

And then comes the final 5%. The part that looks simple on the Gantt chart: “Heat Treatment.”

This is often where timelines unravel. The component—be it a towering pressure vessel, a sprawling skid module, or a complex turbine housing—is too big, too heavy, or too awkward to move. Suddenly, the entire project hinges on a logistical problem that has no easy answer. The “finish line” becomes a chokepoint. But what if we’ve been thinking about the problem backwards?

The Domino Effect of Off-Site Logistics

The traditional solution is straightforward: send it out. You call a fixed-base furnace shop, get on their schedule, and arrange for heavy transport. This works perfectly for thousands of components every year.

But when dealing with oversized or site-integrated structures, this “simple” step introduces a cascade of hidden risks and costs:

- The Transportation Risk: Every lift and transport is a potential point of damage to a high-value asset.

- The Schedule Dependency: Your multi-million dollar project is now waiting in line behind someone else’s job. A one-week delay at the furnace shop can have a month-long ripple effect on your final delivery.

- The Disassembly/Reassembly Cost: Often, components have to be removed from a larger assembly for treatment and then reinstalled, adding significant labor and risk.

These aren’t just inconveniences; they are direct threats to budget and deadline.

A Paradigm Shift: Bring the Furnace to the Fabrication

The most elegant solution to a complex problem is often a simple change in perspective. Instead of asking, “How do we get this massive component to a furnace?” the better question is, “How do we bring a furnace to the component?”

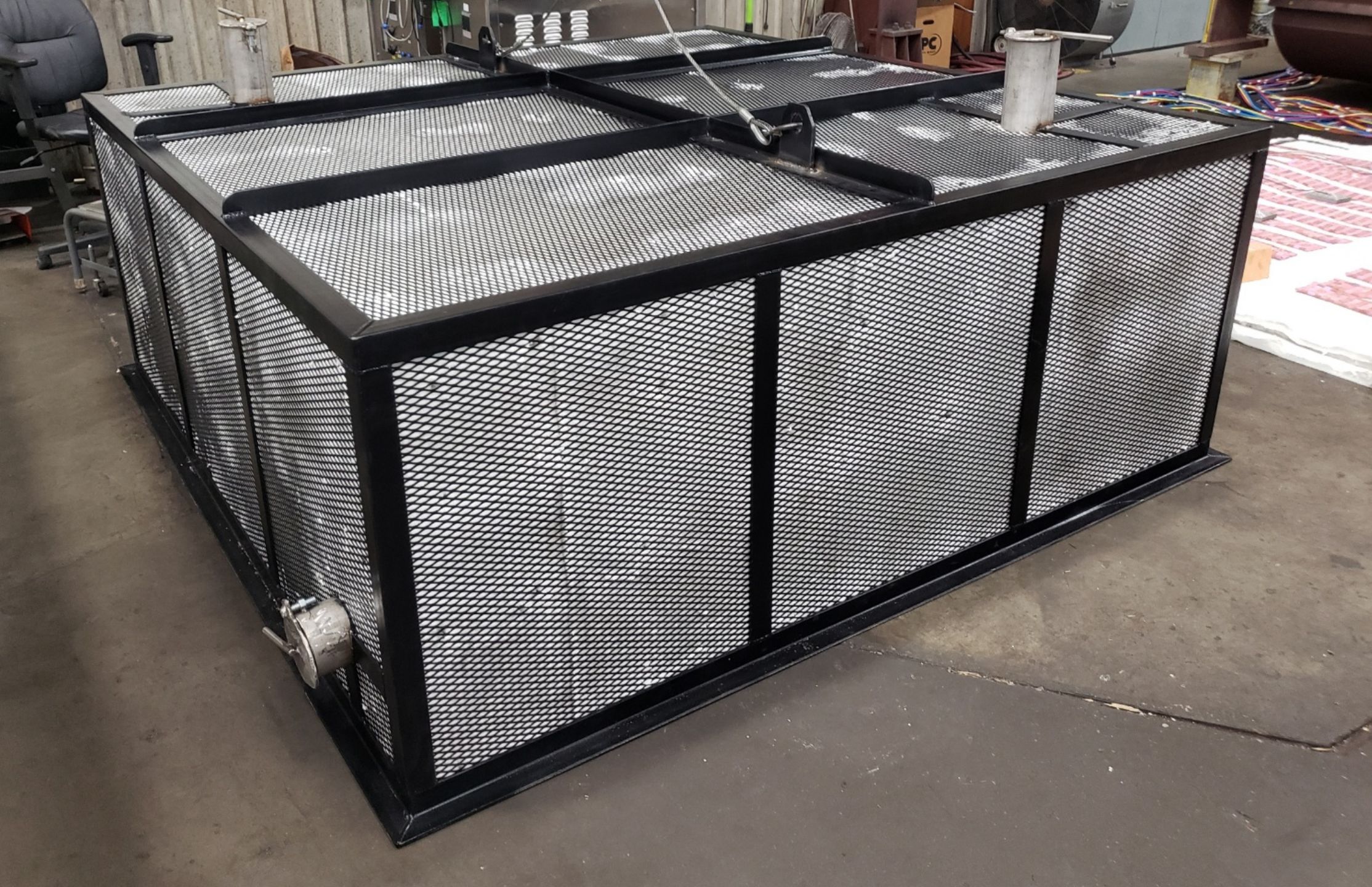

This is the principle behind custom-built, on-site temporary furnaces.

It’s a turnkey thermal solution where a team of specialists arrives at your facility and constructs a high-performance furnace directly around your workpiece. Using modular, insulated panels and precisely controlled combustion or electric heating systems, they create a temporary “hot box” tailored to your component’s exact dimensions.

The result? A code-compliant, perfectly uniform heat treatment cycle is executed right on your shop floor or project site, completely eliminating the transportation bottleneck.

When Does This Approach Make Sense?

This isn’t for every job, but for high-stakes projects, it’s a game-changer. It becomes the obvious choice in several key scenarios:

- For the Unmovable: When the component is a massive pressure vessel, column, or sphere that is simply too large or heavy for any road or rail.

- For the Integrated: When treating a fully assembled skid or module, where disassembly is impractical or would compromise the structure.

- For the Delicate: During a critical refractory dry-out, where precise, slow temperature ramps are essential to prevent damage and ensure the lining’s integrity.

- For the Time-Sensitive: When the project schedule is so tight that waiting for off-site processing is not an option.

Beyond Convenience: The Technical Integrity

A common question is whether a temporary setup can match the quality of a permanent furnace. The answer is an emphatic yes.

Because the furnace is built for the part, engineers can strategically place an array of thermocouples across the entire component, no matter how complex its geometry. This data feeds into a computerized control unit, ensuring that temperature uniformity (+/- 25°F or better) is maintained throughout the entire heating, soaking, and cooling cycle. You receive a complete data chart that provides an auditable, certified record of a perfect, to-spec heat treatment.

Finding the Right Partner for the Final 5%

Executing an on-site thermal cycle is not a commodity service; it’s a specialized engineering discipline. It requires a deep understanding of thermodynamics, metallurgy, logistics, and on-site safety protocols.

At Southern Stress, this is the world we live in. For years, our teams have been working inside refineries, fabrication yards, and power plants across the country, solving these exact “final 5%” challenges. We partner with project managers and engineers to transform their biggest logistical headaches into a seamless, controlled, and documented part of their project plan.

If you’re looking at a component on your project plan and wondering how you’ll ever get it to the finish line, let’s have a conversation.